Energy Running Cost Comparison 4x18W vs Integral 30W 600x600 LED Panel

Energy consumed by a standard 4x18W fluorescent panel depends on its age and build. In the worst case scenario where inefficient magnetic control gear is used the panel wattage can be as high as 112W.

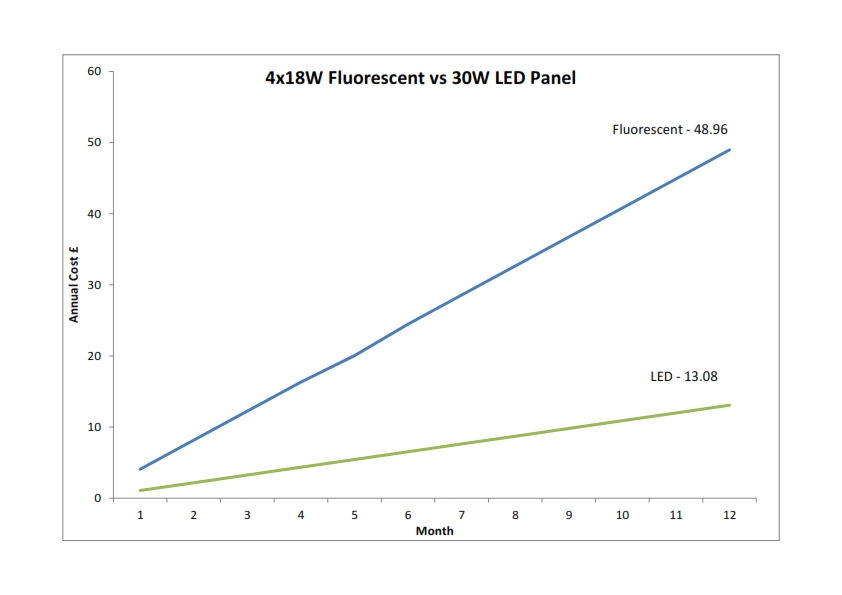

The illustration below shows what savings can be achieved by replacing the unit with an energy efficient equivalent Integral 30W LED 600x600 panel.

The following assumptions are made*:

Old panel wattage: 112W

New LED panel wattage: 30W

Light on hours per day: 12 hours

Light on days per year: 260 days (Mon - Fri)

Tarriff in pence (kWh): 14p

The illustration shows a significant saving of up to 73% can be achievd by switching to a 30W Integral LED panel.

Less energy usage is the major savings component attributable to LED Lighting Technology. However, other factors to consider include heating and maintenance.

Heating

LED light panels produce significantly less heat than their fluorescent equivalents since no heating of gas is required. For offices, and call centres, this equates to less energy required for air conditioning and ventillation.

Maintenance

Conventional compact fluorescent lighting (CFL) panels consists of four T8 tubes, each supported by a starter unit. Every time there is a failure i.e. complete tube outage or flickering, the cost is not only in the component replacement but the manual intervention required to implement the change which often costs more than the component itself. Also depending on where the panel is located, for example at the top of a stair well, specialist equipment may be required to gain access to the panel and that does not come cheap.

Barring the cost of installation Integral LED Lighting Panels offer significant maintenance savings when compared to conventional T8 fluourescent panels.

*Source: Integral-LED

Contacts

Contacts